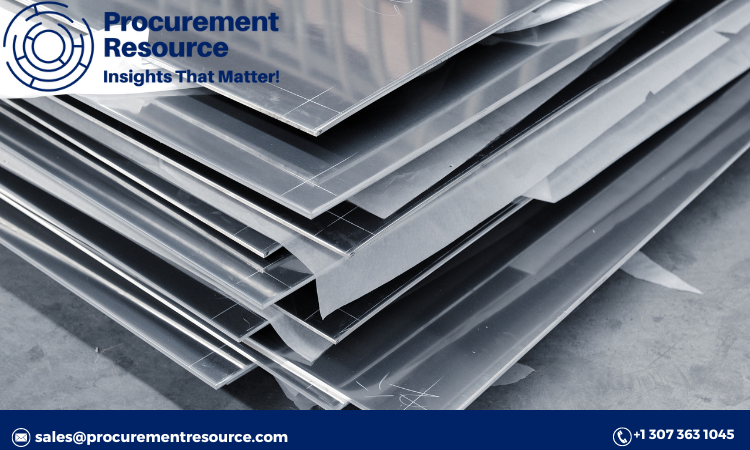

In the world of industrial materials, HDPE sheets stand out for their versatility, durability, and cost-effectiveness. High-Density Polyethylene (HDPE) is a thermoplastic polymer known for its impressive strength-to-density ratio, making it an ideal choice for a variety of applications. In this blog, we’ll delve into the many benefits and uses of HDPE sheets, providing you with a comprehensive understanding of why this material is a go-to option for many industries.

What Are HDPE Sheets?

HDPE, or High-Density Polyethylene, is a type of plastic that is made from petroleum. It is characterized by its high strength, density, and resistance to impact and chemicals. HDPE sheets are produced in various thicknesses and sizes, offering flexibility for a wide range of applications.

Key Benefits of HDPE Sheets

- Durability and Strength

- Impact Resistance: HDPE sheets can withstand significant impacts without cracking or breaking, making them ideal for applications where durability is crucial.

- Wear Resistance: The material’s resistance to abrasion ensures a longer lifespan, even in harsh environments.

- Chemical Resistance

- Corrosion-Free: HDPE sheets are resistant to many chemicals, making them suitable for applications involving corrosive substances.

- Non-Toxic: Being non-toxic and non-leaching, HDPE is safe for use in food and beverage industries.

- Weather Resistance

- UV Stability: HDPE sheets with UV stabilizers can endure prolonged exposure to sunlight without degrading.

- Moisture Resistance: The material is impermeable to water, preventing damage from moisture and making it ideal for outdoor use.

- Ease of Fabrication

- Malleability: HDPE can be easily cut, shaped, and welded, allowing for custom solutions tailored to specific needs.

- Lightweight: Despite its strength, HDPE is lightweight, making it easy to handle and install.

- Cost-Effectiveness

- Affordable: Compared to many other industrial materials, HDPE offers a cost-effective solution without compromising on quality or performance.

- Low Maintenance: Its durability and resistance to various elements reduce the need for frequent replacements and repairs.

Common Applications of HDPE Sheets

- Packaging Industry

- Bottles and Containers: HDPE’s non-toxic nature and chemical resistance make it perfect for packaging food, beverages, and household chemicals.

- Protective Barriers: The material is often used to create protective barriers and liners for packaging sensitive products.

- Construction

- Building Materials: HDPE sheets are used in construction for applications such as wall panels, flooring, and roofing due to their strength and weather resistance.

- Piping Systems: HDPE pipes are common in plumbing and water distribution due to their durability and resistance to corrosion.

- Agriculture

- Irrigation Systems: HDPE’s resistance to chemicals and impact makes it ideal for use in agricultural irrigation systems.

- Greenhouse Linings: Its ability to withstand various weather conditions makes it suitable for greenhouse linings and covers.

- Marine Applications

- Dock Fenders: HDPE sheets are used to protect docks and boats from damage due to their impact resistance and durability.

- Boat Components: Various boat parts, including tanks and seats, are made from HDPE due to its lightweight and non-corrosive properties.

- Automotive Industry

- Fuel Tanks: HDPE is used in the production of fuel tanks for vehicles because of its chemical resistance and durability.

- Interiors: The material is also utilized in creating interior components that require a robust and lightweight solution.

Advanced Applications of HDPE Sheets

- Healthcare and Medical Devices

- Sterilizable Components: HDPE is used in medical trays, containers, and other components that require frequent sterilization. Its resistance to high temperatures and chemicals ensures that it maintains integrity during sterilization processes.

- Prosthetics: Due to its biocompatibility and ease of molding, HDPE is increasingly used in the production of prosthetic limbs and other medical devices.

- Telecommunications

- Cable Insulation: HDPE’s excellent insulating properties make it ideal for protecting fiber optic and other telecommunication cables from environmental damage.

- Enclosures: It is used to create weatherproof enclosures for sensitive telecommunication equipment.

- Energy Sector

- Solar Panel Components: HDPE is utilized in the production of mounting systems for solar panels due to its UV resistance and durability.

- Pipeline Coatings: In the oil and gas industry, HDPE is used as a protective coating for pipelines to prevent corrosion and chemical damage.

- Retail and Display Solutions

- Point of Sale Displays: Retail environments utilize HDPE for creating durable and visually appealing point-of-sale displays.

- Shelving and Storage: HDPE sheets are fashioned into shelving units and storage solutions that can withstand heavy use without degrading.

Advanced Processing Techniques

- Thermoforming

- Detailed Molding: HDPE sheets can be thermoformed into complex shapes and detailed components, allowing for the creation of custom parts for various industries.

- Rapid Prototyping: This technique is also beneficial for rapid prototyping, enabling designers to quickly iterate and develop new products.

- CNC Machining

- Precision Cutting: CNC machines can precisely cut HDPE sheets into intricate shapes, providing high accuracy for technical applications.

- Customization: This method allows for the customization of HDPE components, catering to specific requirements and dimensions.

- Welding and Fabrication

- Strong Joints: HDPE sheets can be welded together to create strong, seamless joints, essential for applications that require a high level of durability.

- Custom Assemblies: Fabrication techniques enable the construction of custom assemblies, such as tanks and ductwork, tailored to specific industrial needs.

Conclusion

HDPE sheets offer a remarkable combination of durability, chemical resistance, and versatility, making them an invaluable resource across multiple industries. Whether you’re in construction, agriculture, packaging, or any other field requiring a reliable material, HDPE sheets provide a practical and cost-effective solution. Their ability to withstand harsh conditions while maintaining their integrity ensures they remain a preferred choice for many applications. Explore the potential of HDPE sheets for your next project and experience the benefits of this exceptional material.