Industrial high-pressure washers are the undisputed titans of the cleaning world. These behemoths, welding pressures that can exceed a staggering 5000 PSI, are engineered to obliterate even the most stubborn industrial grime, paint, and contaminants. If you’re battling the unrelenting dirt and debris of a demanding industrial environment, an industrial high pressure washer is the ultimate weapon in your cleaning arsenal.

industrial high pressure washer locates programs across various industries, consisting of production, transportation, creation, agriculture, food processing, and oil and gasoline. They are used for cleaning production equipment, motors, industrial machinery, processing vegetation, warehouses, and greater. The versatility of those washers is stronger with the aid of adjustable pressure settings and a number of nozzle alternatives, permitting operators to personalise cleansing responsibilities consistent with unique requirements.

Unreliable cleaning performance:

-

Raw Power Released: Industrial high-pressure washers boost PSI (pounds per square inch) that goes beyond just cleaning – they earn their way to an industrial grade blast to thereby remove years of accumulated dirt, paint layers and caked-on dirt merciless efficiency can have a strong shake of water

-

The Art of Flow Rate: Although PSI refers to raw cleaning capacity; flow rate (measured in gallons per minute) plays an important role in quality cleaning processes Industrial washes provide GPM options. High flow patterns (greater than 5 GPM) are accomplished for rapid surface cleaning; while low flows (in the range of 3 GPM) are more intense, high pressure bursts provide pinpoint clean-up of particularly difficult deposits.

Conquering Industrial Cleaning Challenges:

-

Construction Winners: From carefully removing concrete splatter from poured foundations to cleaning heavy equipment and cleaning supplies for extra work, high-pressure industrial washing machines contain large construction laundries.

-

Promoters of Industrial Hygiene: Maintaining a clean and spotless environment in industrial areas is of utmost importance. These washing machines excel in things like hot water disinfecting surfaces (on hot water paints), removing paint for repainting for maintenance lend themselves to the production of new lines, as well as keeping the exterior of the buildings free from industrial contamination.

-

Fleet Maintenance Powerhouses: Washing heavy lore’s, buses and other machinery is a delicate process in which dirt, grease and roads are effortlessly removed with high-tech pressure washing power that the layered impurity gets rid of . They also feature a glossy face that reflects a professional image.

-

Professional Floor Recycling: Industrial areas tend to have a lot of dirty areas such as sidewalks, parking lots, gutters, the exterior of the building, etc. An industrial high-pressure washer tackles these challenges with ease, restoring their original beauty, functionality, and safety standards.

Beyond Brute Force: Features for Professional Applications:

-

Built to Withstand: High-pressure industrial washing machines are built to withstand the rigours of constant business. Heavy-duty materials and rugged construction ensure reliable performance, even in the harshest environments.

-

For your Needs: High-pressure industrial washing machines come in gas- and electric-powered varieties. Gas-powered machines offer unparalleled portability and are ideal for handling multi-site operations. Electric options give it quieter operation, making it suitable for noisy environments or furnishings.

-

Power Selection using Nozzles: Careful selection of nozzles allows for standard cleaning methods to be adopted. Focus nozzles provide a strong jet for pinpoint cleaning of machinery or sensitive work. Fan water provides an extensive sprinkler system for cleaning very large open areas. Additionally, specialised tubes are available for specific applications, such as rotating tubes for pipe cleaners or undercarriage cleaners for handling the underbelly of vehicles

-

Safety First, Always: The high pressure of these devices calls for strict safety measures. Mechanical washing machines are generally equipped with GFCI outlets (ground-fault circuit interrupters) that disconnect electricity, and are equipped with trigger locks to prevent accidental operation Wear appropriate personal protective equipment ( PPE) always in the presence of heavy weapons has gloves, side -shielded safety glasses and good traction sturdy shoes.

Professional Considerations for Optimal Results:

-

Page Alignment: Not all pages are created equal. Some materials can be damaged by extreme pressure. Always refer to the user manual and test in a small, inconspicuous area before performing a thorough cleaning.

-

Professional Training: In some applications, especially those involving sensitive materials, hazardous materials, or working at heights, employee training in safe techniques and effective pressure washing can be necessary. Not only does this provide the best possible cleaning but it also prioritises the safety of the user and those around them.

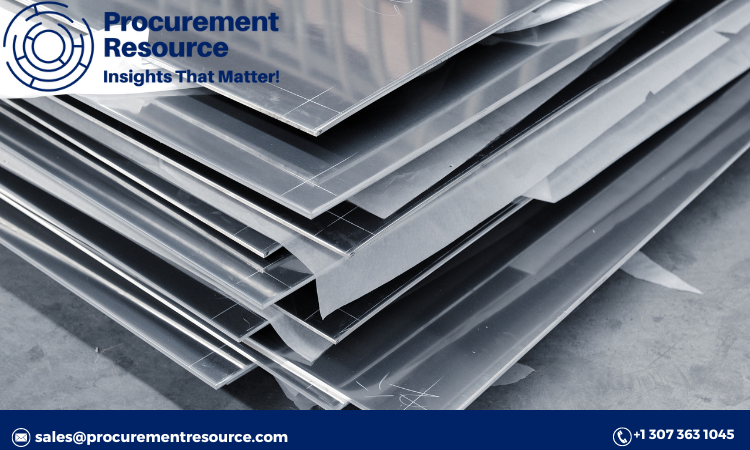

Properties of Industrial Pressure Washers

High Pressure Capacity: Industrial pressure washers are known for their high PSI (pounds per square inch) rating, which often exceeds 3000 PSI. This allows for the delivery of high-pressure pipelines that can easily penetrate and lift tight deposits.

Durable Construction: Made from heavy-duty materials such as stainless steel frame reinforced components, washers are designed to withstand harsh industrial conditions; they are corrosion resistant, ensuring durability. It was a reliable project.

Powerful Appliances: Industrial appliances are equipped with powerful electric motors or gasoline engines, providing sufficient power for constant use and maintaining constant pressure and flow

High Water Flow: These washing machines have a high gallon-per-minute (GPM) rating that will make cleaning easier by delivering a sufficient amount of water to wash away debris quickly

Integrated Heating System: Some models are equipped with an integrated heating system or can be connected to external hot springs. This feature allows steam or hot water to be used for advanced cleaning, and is particularly effective for degreasing and cleaning surfaces

Large Wash Tanks: Industrial washers have the option of large wash tanks or dishwashers. This power operators and cleaning agents directly into the water stream increases cleaning efficiency by allowing operators to apply detergents directly to the water as needed.

The Final Verdict: An Investment in Industrial Cleanliness

Industrial high-pressure washers are not mere cleaning tools; they are an investment in industrial hygiene, efficiency, and safety. By understanding their capabilities, limitations, and safety protocols, you can leverage the immense power of an industrial high pressure washer to achieve exceptional cleaning results on even the most demanding jobs. Jetwave industrial pressure washers stand out for their performance, versatility, durability and environmental considerations, making it an essential tool in maintaining cleanliness and productivity across industries whether dealing with maintenance