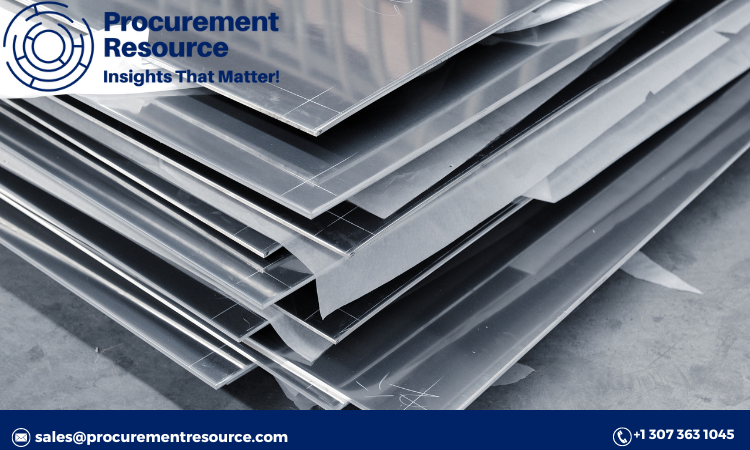

Choosing the right spare parts for your DOOSAN machinery is crucial to ensure its longevity and efficiency. In this comprehensive guide, we’ll walk you through everything you need to know to make the best choice for your equipment. Whether you’re a seasoned professional or new to machinery maintenance, this blog will help you understand the key factors to consider.

Understanding the Importance of Genuine DOOSAN Spare Parts

When it comes to machinery, the quality of spare parts can significantly impact performance and lifespan. Genuine DOOSAN spare parts are specifically designed to fit and function perfectly with your equipment. Using genuine parts ensures that your machinery operates at its best, minimizing the risk of breakdowns and costly repairs.

NOTE : “Discover top-quality DOOSAN SPARE PARTS IN DUBAI today! Ensure your machinery runs smoothly with our reliable and genuine parts. Contact us now to get the best deals and expert assistance tailored to your needs!”

Why Genuine Parts Matter

Genuine DOOSAN parts are made to the highest standards, ensuring reliability and durability. They are tested and certified to meet the manufacturer’s specifications, guaranteeing compatibility and performance. Non-genuine parts, on the other hand, might be cheaper initially but can lead to frequent malfunctions and even permanent damage to your machinery. Investing in genuine parts ultimately saves you time, money, and hassle in the long run.

Researching and Selecting the Right Parts

Finding the correct spare parts for your DOOSAN machinery involves thorough research. Start by identifying the specific needs of your equipment. Refer to your machinery’s manual or consult with a professional to determine the exact parts required. Once you know what you need, it’s time to explore your options.

Where to Find Reliable Information

Online resources, official DOOSAN websites, and authorized dealers are excellent places to gather information. Reading reviews and seeking recommendations from industry professionals can also provide valuable insights. Ensure that the parts you select are compatible with your specific machinery model. Cross-referencing part numbers and verifying specifications are critical steps in this process.

Evaluating Suppliers and Dealers

Choosing a reliable supplier or dealer is just as important as selecting the right parts. Not all suppliers offer the same level of quality and service. To ensure you get the best parts, it’s essential to evaluate potential suppliers thoroughly.

Criteria for Choosing Suppliers

Look for suppliers with a good reputation in the industry. Check their reviews, ask for references, and verify their certification as authorized DOOSAN dealers. It’s also beneficial to select suppliers who offer warranties and have a return policy. This gives you peace of mind knowing that you can return or exchange parts if needed. Additionally, consider suppliers who provide technical support and after-sales service. This can be invaluable if you encounter any issues with the parts.

Understanding the Cost vs. Quality Balance

While it might be tempting to opt for cheaper spare parts, this can often lead to higher costs in the long term. Balancing cost and quality is crucial when choosing DOOSAN spare parts. High-quality parts may have a higher upfront cost but will last longer and perform better, reducing the need for frequent replacements and repairs.

Long-Term Savings

Investing in high-quality parts ensures that your machinery remains operational for a longer period. This not only saves you money on replacements but also reduces downtime, which can be costly in terms of productivity. When evaluating the cost, consider the total cost of ownership rather than just the initial purchase price. This approach helps you understand the true value of investing in quality parts.

The Role of Maintenance and Regular Checks

Regular maintenance and checks are vital to ensure that your machinery continues to function efficiently. Even the best spare parts can wear out over time if not properly maintained. Implementing a routine maintenance schedule helps in early detection of potential issues and extends the lifespan of your equipment.

Creating a Maintenance Schedule

Work with a professional to create a detailed maintenance schedule for your machinery. This should include regular inspections, cleaning, lubrication, and timely replacement of worn-out parts. Keeping a maintenance log can help track the condition of your equipment and the parts used, making it easier to predict and prevent potential problems.

The Impact of Environmental Factors

Environmental conditions play a significant role in the performance and durability of your machinery and its parts. Factors such as temperature, humidity, and exposure to harsh elements can affect how long your parts last and how well they perform.

Adapting to Environmental Challenges

To mitigate the impact of environmental factors, consider using parts that are specifically designed to withstand such conditions. For instance, if your machinery operates in a high-humidity environment, look for parts that are resistant to rust and corrosion. Regularly check and maintain these parts to ensure they are not adversely affected by their operating environment.

Leveraging Technology for Better Maintenance

Advancements in technology have made it easier to maintain and monitor machinery. Utilizing modern tools and software can enhance the efficiency of your maintenance practices and help you choose the best spare parts for your needs.

Using Predictive Maintenance Tools

Predictive maintenance tools can analyze data from your machinery to predict when parts might fail. This allows you to replace parts before they cause a breakdown, ensuring continuous operation. Investing in such technology can provide significant long-term benefits, including reduced downtime and maintenance costs.

Training and Educating Your Team

Ensuring that your team is well-trained in machinery maintenance and the use of spare parts is crucial. Proper training helps in the correct installation and handling of parts, which can significantly extend their lifespan and improve the overall efficiency of your machinery.

Ongoing Education

Provide ongoing training sessions for your team to keep them updated on the latest maintenance techniques and best practices. Encourage them to follow manufacturer guidelines and consult with professionals when needed. A well-informed team is a valuable asset in maintaining the reliability and performance of your machinery.

Conclusion: Making Informed Decisions

Choosing the best DOOSAN spare parts for your machinery is a multifaceted process that requires careful consideration of various factors. By understanding the importance of genuine parts, conducting thorough research, selecting reliable suppliers, balancing cost and quality, and implementing regular maintenance, you can ensure that your machinery operates efficiently and lasts longer.

Key Takeaways

- Invest in genuine DOOSAN parts for reliability and durability.

- Conduct thorough research and select parts compatible with your machinery.

- Choose reputable suppliers who offer warranties and after-sales support.

- Balance cost and quality to achieve long-term savings.

- Implement regular maintenance and adapt to environmental factors.

- Utilize technology for predictive maintenance and better efficiency.

- Train and educate your team to ensure proper handling and installation of parts.

By following these guidelines, you can make informed decisions that will keep your DOOSAN machinery in optimal condition, ensuring smooth and efficient operations for years to come.

For more insightful articles related to this topic, feel free to visit algo360i