Introduction to Galvanized Zinc Paint

Galvanized zinc paint plays a critical role in protecting metal surfaces from corrosion, extending their lifespan, and maintaining their appearance. The addition of zinc into the paint formulation enhances its protective properties, making it an ideal choice for various applications, especially in environments prone to rust and corrosion. This article delves into the significance of galvanized zinc paint, its applications, and the pivotal role of aerosol spray paint suppliers in the industry.

Understanding Galvanized Zinc Paint

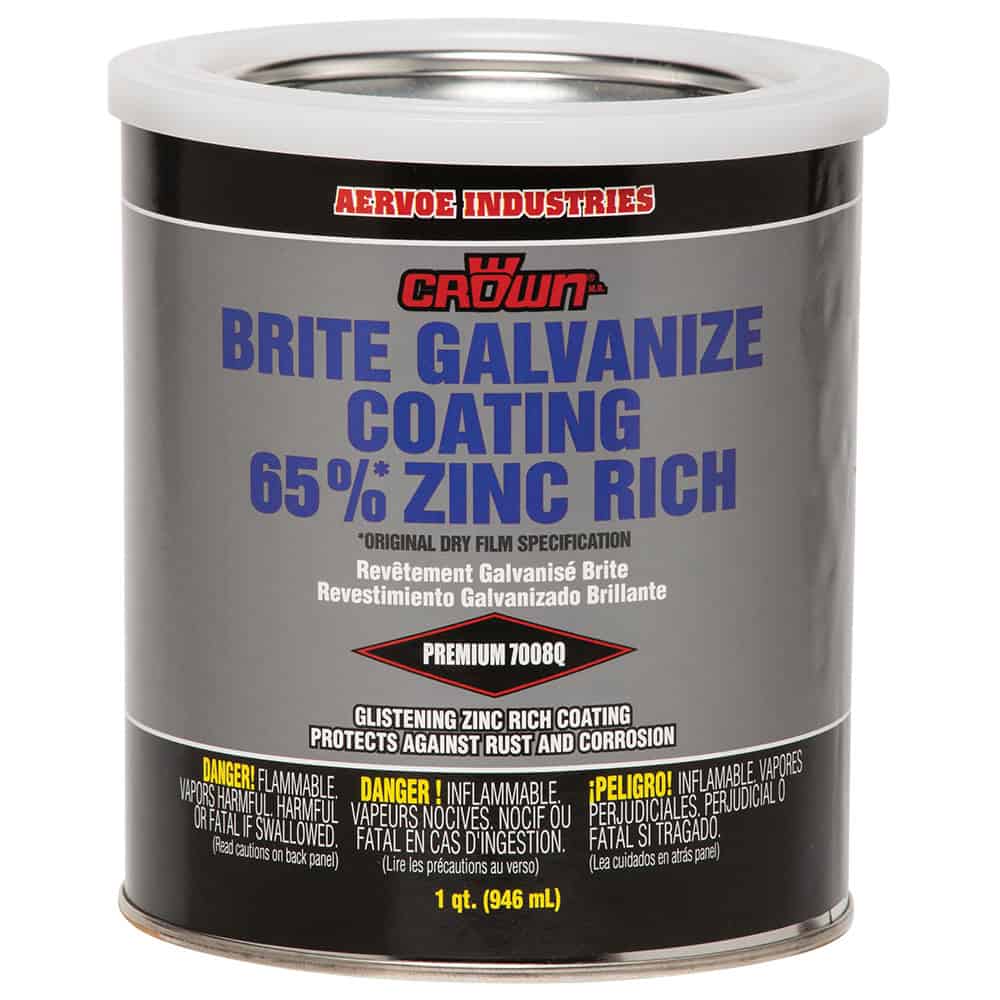

What is Galvanized Zinc Paint?

Galvanized zinc paint, often referred to as zinc-rich paint, contains a high concentration of zinc dust mixed with a resin binder. This type of paint provides cathodic protection, similar to hot-dip galvanization, which is a process where steel is coated with a layer of zinc to prevent rusting. The zinc in the paint serves as a sacrificial anode, meaning it will corrode first before the underlying metal does, thereby offering excellent protection against rust.

How Does It Work?

The mechanism behind galvanized zinc paint involves the electrochemical relationship between zinc and iron (steel). When the paint is applied to a metal surface, the zinc particles create a physical barrier that prevents moisture and oxygen from reaching the metal. Additionally, because zinc is more reactive than iron, it will corrode preferentially, protecting the steel underneath from oxidation and corrosion. This dual action of barrier protection and sacrificial protection is what makes galvanized zinc paint highly effective.

If you want to know more information about aerosol spray paint suppliers visit Revo Paint.

Applications of Galvanized Zinc Paint

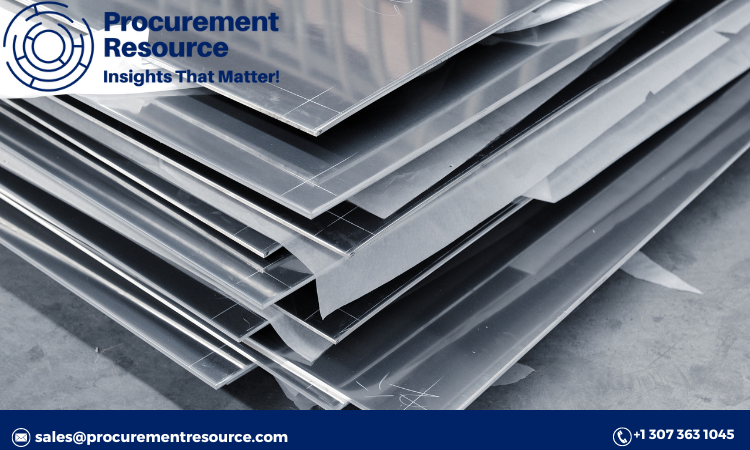

Industrial Use

In industrial settings, galvanized zinc paint is commonly used on steel structures, pipelines, storage tanks, and bridges. These environments are often exposed to harsh weather conditions, chemicals, and mechanical wear, making corrosion protection essential. The paint’s ability to withstand extreme conditions ensures that these structures remain durable and safe over time.

Marine Environments

Marine environments are particularly challenging due to the high salinity of seawater, which accelerates the corrosion process. Galvanized zinc paint is extensively used on ships, offshore platforms, and harbor structures. The paint’s excellent adhesion and resistance to saltwater make it ideal for protecting metal surfaces in these corrosive environments.

Automotive Industry

In the automotive industry, galvanized zinc paint is applied to various car parts, including the underbody, to protect against rust caused by road salt and moisture. This helps in extending the vehicle’s lifespan and maintaining its structural integrity.

Household and DIY Projects

For household applications and DIY projects, galvanized zinc paint is used on fences, railings, and outdoor furniture. It provides a cost-effective solution for preventing rust and maintaining the aesthetic appeal of metal items.

The Role of Aerosol Spray Paint Suppliers

Convenience and Accessibility

Aerosol spray paint suppliers play a crucial role in making galvanized zinc paint accessible to a broader audience. The convenience of aerosol spray cans allows for easy application, especially for smaller projects or touch-ups. This format eliminates the need for specialized equipment and reduces preparation time, making it a popular choice among DIY enthusiasts and professionals alike.

Quality and Variety

Reputable aerosol spray paint suppliers offer a wide range of galvanized zinc paint products, ensuring that customers can find the right formulation for their specific needs. These suppliers often provide paints with different levels of zinc content, varying drying times, and finishes (e.g., matte, satin, gloss), catering to diverse application requirements.

Technical Support and Expertise

Aerosol spray paint suppliers not only provide products but also offer valuable technical support and expertise. They can guide customers on the proper preparation of surfaces, the correct application techniques, and the ideal environmental conditions for painting. This support is crucial in ensuring that the paint performs as expected and provides long-lasting protection.

Innovation and Sustainability

The best aerosol spray paint suppliers are at the forefront of innovation, constantly improving their products to enhance performance and sustainability. This includes developing low-VOC (volatile organic compounds) formulations to reduce environmental impact and improve indoor air quality. Sustainable packaging solutions and eco-friendly manufacturing processes are also priorities for leading suppliers.

Choosing the Right Galvanized Zinc Paint

Factors to Consider

When selecting galvanized zinc paint, several factors should be considered to ensure optimal performance:

-

Zinc Content: Higher zinc content typically provides better protection. Paints with at least 90% zinc in the dry film are considered high-performance.

-

Surface Preparation: Proper surface preparation is crucial for the paint to adhere correctly. This may involve cleaning, degreasing, and sometimes abrasive blasting.

-

Application Method: While brush and roller applications are suitable for larger surfaces, aerosol spray cans are ideal for smaller areas and touch-ups.

-

Environmental Conditions: Consider the environmental conditions where the paint will be applied, such as humidity, temperature, and exposure to chemicals.

Recommendations

For industrial and marine applications, a high-zinc content paint applied with professional equipment may be necessary to achieve the best results. For household and DIY projects, aerosol spray cans from reputable suppliers offer a convenient and effective solution.

Case Studies

Industrial Application: Steel Bridge Protection

A steel bridge located in a coastal area was experiencing significant corrosion due to exposure to saltwater and humid conditions. A comprehensive maintenance project was undertaken, which involved abrasive blasting to remove existing rust, followed by the application of a high-zinc content galvanized zinc paint. The project demonstrated the paint’s excellent adhesion and corrosion resistance, significantly extending the bridge’s service life.

Marine Application: Offshore Platform Maintenance

An offshore oil platform required regular maintenance to protect its metal structures from the harsh marine environment. Using aerosol spray cans of galvanized zinc paint, maintenance crews were able to quickly and efficiently apply protective coatings to critical areas. The ease of application and quick drying time minimized downtime and ensured continuous protection against corrosion.

Household Application: Outdoor Furniture Restoration

A homeowner wanted to restore a set of outdoor metal furniture that had begun to rust. Using aerosol spray cans of galvanized zinc paint, the homeowner was able to clean and coat the furniture, effectively stopping the rust and giving the furniture a fresh, new look. The project highlighted the convenience and effectiveness of aerosol spray paint for DIY applications.

Future Trends

Advances in Galvanized Zinc Paint Technology

The future of galvanized zinc paint is likely to see further advancements in formulation, enhancing its protective properties and ease of application. Innovations may include the development of nanotechnology-based coatings that offer superior adhesion and durability.

Environmental Considerations

As environmental concerns continue to grow, the paint industry is expected to focus more on developing eco-friendly products. This includes reducing the VOC content in paints and adopting sustainable manufacturing practices. Aerosol spray paint suppliers will play a crucial role in this transition by offering greener products and educating consumers about their benefits.

Digital Solutions and E-commerce

The rise of e-commerce is transforming the way consumers purchase paint products. Aerosol spray paint suppliers are increasingly leveraging digital platforms to reach a wider audience, offering online tutorials, virtual consultations, and easy ordering processes. This trend is likely to continue, making it easier for consumers to access high-quality galvanized zinc paint products and expert advice.

Conclusion

Galvanized zinc paint is an essential tool in the fight against corrosion, offering reliable protection for metal surfaces in various environments. The role of aerosol spray paint suppliers is critical in ensuring that these products are accessible, high-quality, and supported by technical expertise. By understanding the importance of galvanized zinc paint and choosing the right products and suppliers, consumers can effectively protect their metal assets and extend their lifespan. As the industry evolves, continued innovation and a focus on sustainability will shape the future of galvanized zinc paint and its applications.